Les Tissus Geo. Sheard Ltée.

84 Rue Merrill

Coaticook, Québec, J1A 1X1

Greenleaf LogoThe Greenleaf logo is a trademark of Geo. Sheard Fabrics and designates fabrics in which the polyester content is 100% recycled. The recycling of polyester reduces the environmental footprint left from processing petroleum products into virgin polyester. The ensuing reduction in the energy required for the manufacturing process results in lower emission levels and less waste. |

|

|

|

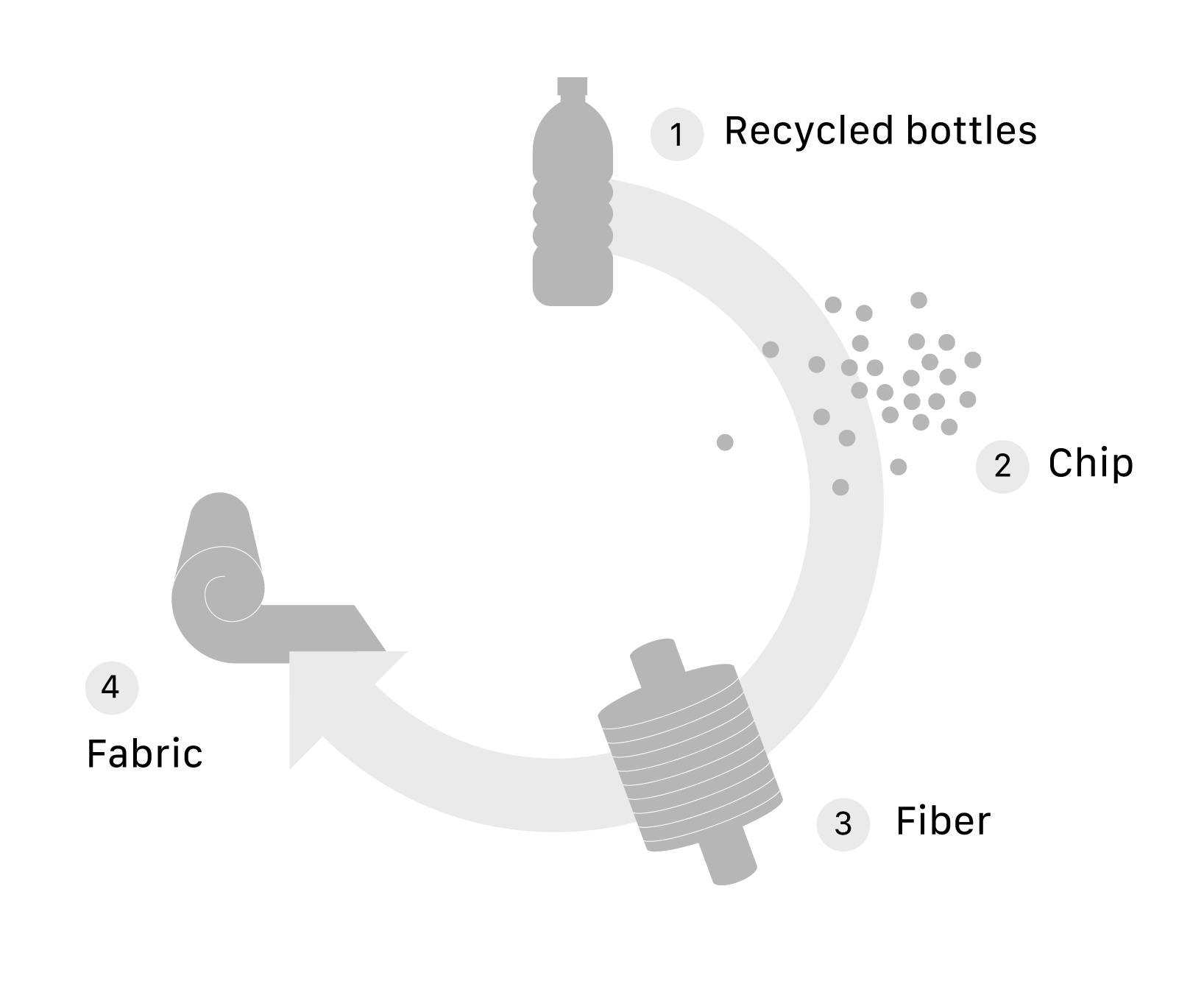

Post ConsumerRecycled Polyester

Learn more at www.repreve.com |

|

Our Ocean™

Learn more at www.repreve.com |

|

|

|

GreenShield® FinishGreenShield® is the greenest and safest multifunctional finish on the market today, reducing the use of chemistries that are persistent in the environment or harmful to life. GreenShield® can be applied by GSF in-house and this allows for shorter lead times on fabrics. Other competing finishes must be applied to fabrics by third part finishers which increases lead times and transportation costs. |

GreenShield® ZERO

|

|

|

|

GreenShield® Advantages

Learn more at www.greenshieldfinish.com |

|

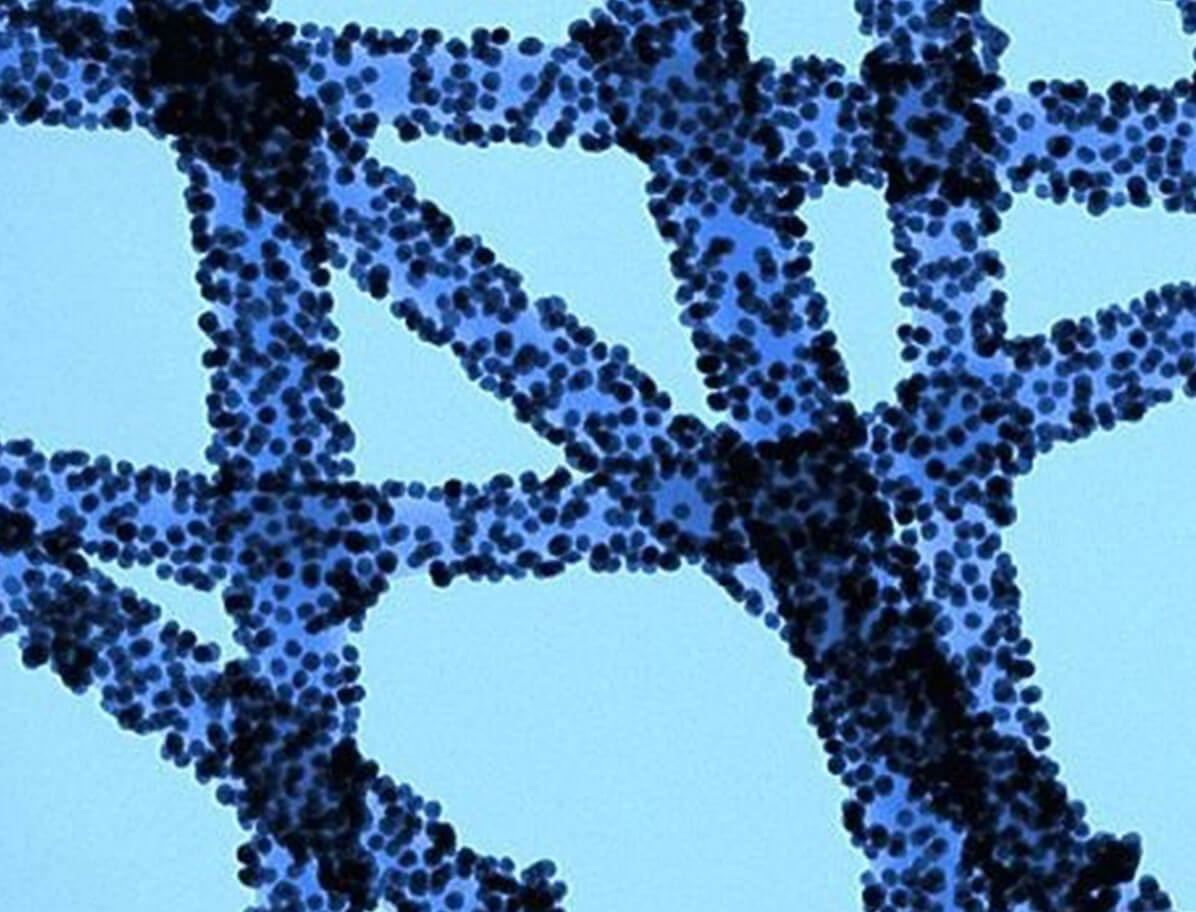

BiomimicryGreenShield® has taken a page from nature’s design through the use of nanoparticles on the surface of the fabric. GreenShield® creates a pocket of air which causes moisture droplets to bead up and roll, preventing absorption and naturally protecting the surface of the fabric. |

|

|

|

Nvirosoft™ Backing

|

|

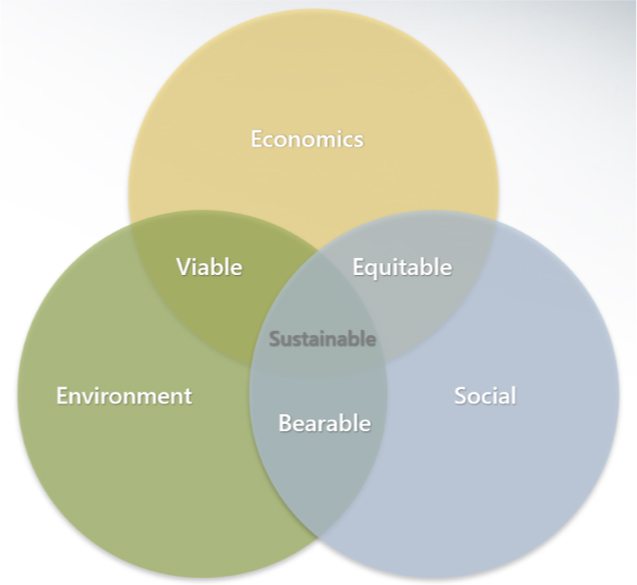

Sustainable DevelopmentGeo. Sheard Fabrics is committed to the principles of sustainable development: growing our business while improving our environmental performance and the working conditions of our employees. Our continuous improvement philosophy focuses on always looking for new ways to increase the efficiency of our operations and the performance of our products while decreasing our environmental footprint and the use of natural resources such as energy and water. |

|

|

|

Environmental ManagementWe are a registered Industrial Energy Innovator, part of a select group of Canadian companies that are making energy efficiency a priority. This initiative is part of the Canadian Industry Program for Energy Conservation (CIPEC), a joint industry-government program sponsored by Natural Resources Canada’s Office of Energy Efficiency. |

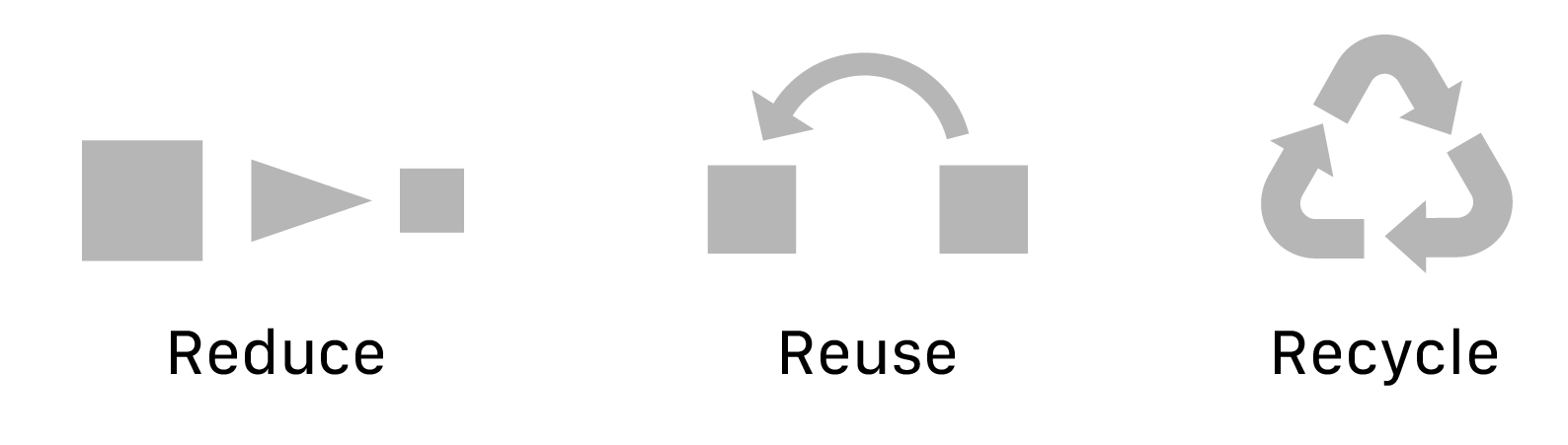

Pollution PreventionPollution prevention is a guiding principle that we adhere to in managing our business. Reducing or preventing pollution at the source is not only sound environmental practice, but it also leads to increased efficiency in the use of raw materials, energy, water and other natural resources, which leads to higher overall productivity and lower manufacturing costs. We abide by the principles of the three Rs. We continually strive to find new ways to reduce waste generated within our operations and reuse and recycle materials whenever possible in order to minimize the volume of waste sent to the landfill. |

|

|

|

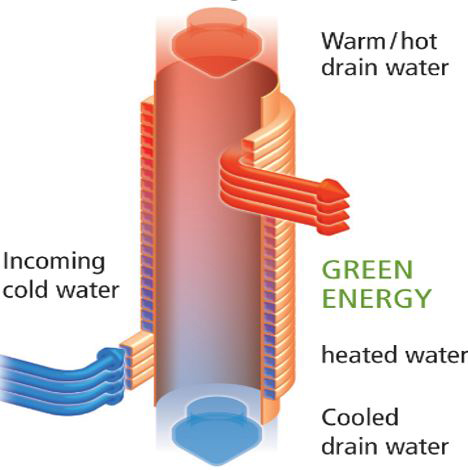

Energy EfficiencyWe have invested in several energy efficiency projects:

These projects have led to the following savings:

|